Selection and application of forward and backward centrifugal fans

Centrifugal fans can be divided into forward centrifugal fans and backward centrifugal fans. Different configurations determine different performances and applications.

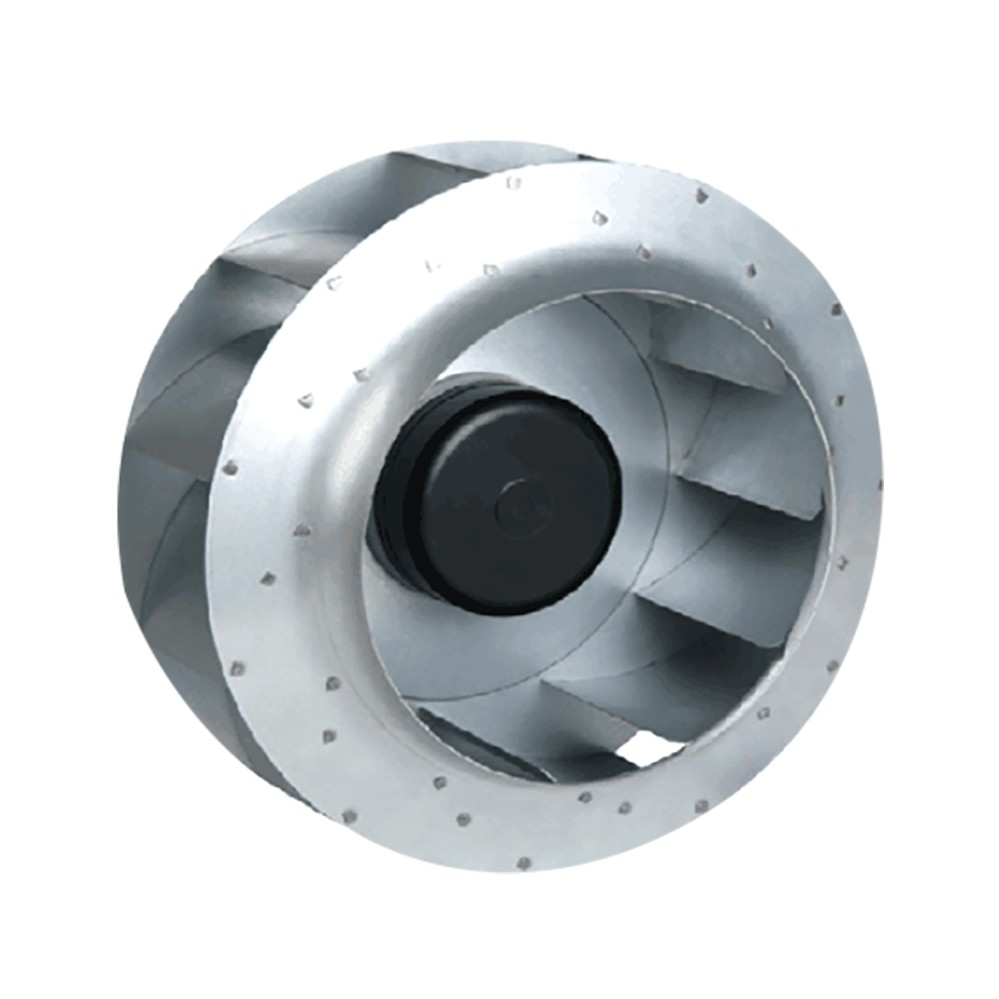

Composition and application of backward centrifugal fan:

The fan is composed of an external rotor asynchronous motor, plastic/aluminum impeller, etc. The low temperature rise of the motor has the unique advantages of ventilation and self-cooling. Thereby extending the life reliability of the fan. The fan is a backward curved impeller, which has the characteristics of compact structure, large air volume, high static pressure, low vibration, low noise, and easy installation.

It is mainly used for purification workbench, purification unit, ventilation duct dust removal, purification air conditioning system, environmental protection and pollution control and other refrigeration equipment supporting work.

Composition and application of forward centrifugal fan:

This series of fans is composed of an external rotor motor, a plastic forward curved or metal forward curved impeller, a plastic or metal volute, and has the characteristics of compact structure, small size, light weight, easy installation and use.

It is widely used in automatic control devices, forced ventilation of electronic equipment, indoor duct dust removal, exhaust, heat removal, environmental protection, air purification and pollution control.

The forward and backward centrifugal fans mainly refer to the blades of the assembled fan. The forward type is generally called a blower, and the backward type is generally called an induced fan. The difference is the length of the impeller rail and the edge of the impeller.

The forward direction is parallel to the edge of the impeller, and the exit angle of the impeller is greater than 90 degrees. The forward impeller is also called a forward impeller. The forward impeller is mostly high-pressure. The backward direction is not parallel to the impeller, and the length is a few centimeters or millimeters away from the edge of the impeller. The impeller exit angle is less than 90 degrees. The backward impeller is also called the backward impeller. The backward impeller is mainly medium pressure.

There are three main differences:

① Power

To overcome the static pressure head of the system, the forward centrifugal fan is smaller than the backward centrifugal fan. Since the channel in the backward blade fan is gradually enlarged, its hydraulic loss is smaller than that of the forward type. Therefore, the efficiency of the forward centrifugal fan is lower than that of the backward centrifugal fan.

② Consumption

consumption Since the efficiency of the forward centrifugal fan is lower than that of the backward centrifugal fan, its power consumption is greater than that of the backward centrifugal fan.

③ Noise

The running noise of the forward centrifugal fan is greater than that of the backward centrifugal fan.

ERP

ERP en

en

search

search